China’s role and importance in global trade cannot be undermined, both as a primary producer of high-value products and a consumer of industrial commodities. Wuhan specifically is very crucial to the worldwide supply chain. While Wuhan has been a traditional manufacturing base for decades, it has also supported a massive industrial shift in modern China.

Major industries based in Wuhan include high technology (biology engineering, pharmaceuticals, optoelectronic technology, and environmental protection) and modern manufacturing (steel, iron, and automotive). Putting this into context, over 200 Global 500 firms have a presence directly in China, Wuhan to be specific.

Wuhan, one of the world’s leading manufacturing hubs, experienced perhaps the most devastating impacts of the Covid-19 pandemic. The pandemic had a domino effect of supply shortages and plant closures, extending across the supply chain network leading to critical supply chain disruptions.

So, What’s Next

Following a global shortage of essential technical equipment due to the disruption in the worldwide supply chain, IT managed service providers are experiencing a surge in IT consulting as companies and businesses scramble for the foreseeable future. The impact of Covid-19 on industries and supply chains has shifted enterprises’ focus from on-premises hardware and technology equipment to remotely managed services. For businesses to deal with these myriad supply shocks, it’s important to understand what led to the global supply chain crisis, what technologies were affected, and what businesses can do to help themselves.

Let’s take a closer look.

Factors Behind the Global Supply Chain Crisis

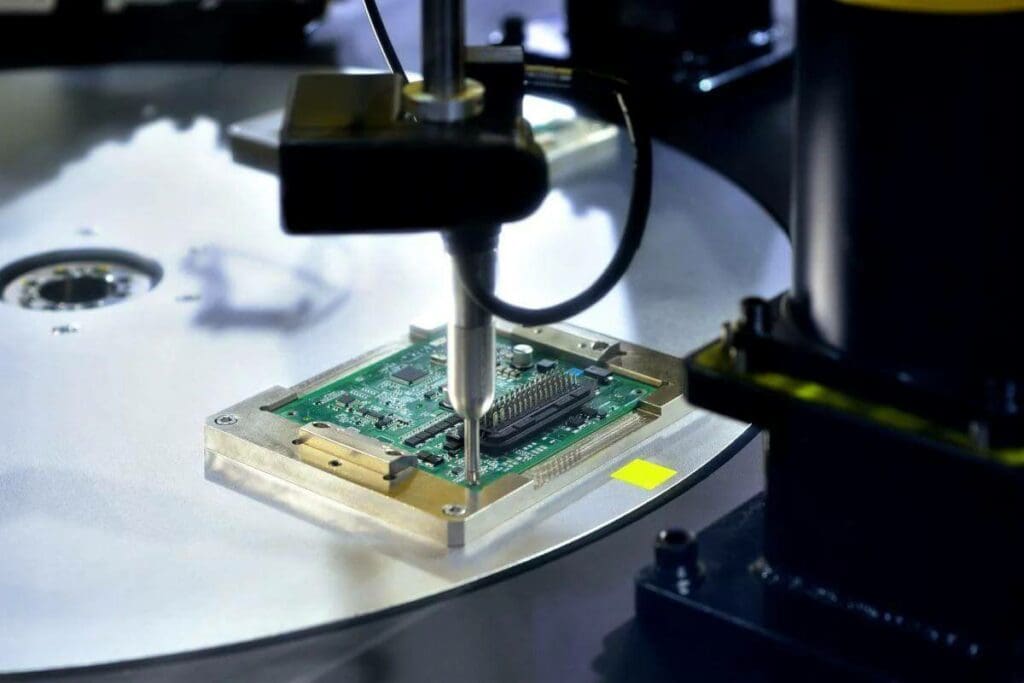

Foremost, the global supply chain crisis is primarily due to crucial material components being underproduced. In turn, this under-production of crucial material components delays the availability and increases the cost of products. Indeed, the Covid-19 pandemic caused severe supply shocks in the IT hardware components. This shortage of processors and semiconductors affected the supply of crucial resources, including; smartphones, vehicles, electronic and IT hardware equipment.

According to research, processors and semiconductors are used in virtually everything today. From computers, cell phones, and toasters; to home dryers, heating equipment, and washing machines, all this equipment uses crucial resource components. Most of this equipment and devices are becoming more innovative and more complex, thus leading to a demand for critical material components (semiconductors and processors).

In 2020, experts predicted that spending on non-essential products would decrease. This prediction was backed by several pointers, including; remote working, increased unemployment, and business collapse. Following the shrinking demand for non-essential products, components like semiconductors and processors were scaled back.

A New Wake

Shortly after the covid pandemic came remote working and education. This led to a corresponding demand for smart devices such as chrome books, laptops, monitors, cell phones, and accessories as individuals and schools strived to remain connected via cloud computing. Couple this rapid uptake with lean manufacturing methods, and you have a perfect storm for disruption.

Technology Equipment Hardest Hit by the Pandemic

Most technology equipment was affected by the pandemic. However, IT hardware components were the hardest hit following shortages in crucial components such as processors and semiconductors. Sticking specifically to work-related and IT technology, some of the material products affected include:

- Computer components

- Desktops

- Laptops

- Servers

- Mobile phones

- Tablets

- Networking equipment (graphic cards, processors, and power supplies)

- Monitors

- Laptop docks

- Input and output devices

Skyrocketing Costs and Lead Times

The biggest challenge businesses have in ordering work-related technology equipment is that lead times have ballooned significantly. Where you may have previously seen a 10 to 20-day lead-time, you’re now looking at a three-month timeframe.

A shortage of crucial technology components means that suppliers of hardware components will see a surge in prices as they curb the demand for limited resources. In addition, the shortage of crucial equipment such as computers, laptops, servers, and networking equipment will see a surge in business costs as companies finance these particular pieces of hardware.

In the long term, businesses will increase operational costs to accommodate the price hikes of technology hardware components. That’s the reason serious players willing to phase out their competitors are replacing on-premise hardware with off-premise automated software solutions.

For instance, the uptake of cloud computing services to automate crucial business operations like invoicing, procurement, marketing, and sales is on the rise. Businesses are also eying at managed service providers to deliver on-demand, customer-deployed automation solutions. While you might not have adopted anything during this supply chain disruption, it’s not late to join this bandwagon of forward-looking and fast-thinking enterprises.

Here are a few strategies to minimize disruption during this supply chain shortage.

Prior Planning

Businesses should keep tabs on what they’re expecting. If you’re looking forward to hiring new staff in the next 5-12 months, consider waitlisting for the technology and work-related equipment they will use. If you’re looking to expand your network and computing systems, consider scaling your cybersecurity strategy to accommodate this dynamic shift.

Flexibility

As managed service providers, we advise our clients to be flexible with configurations and brands. For instance, you may access a personal computer with a slightly different processor, storage, or memory. Though this computer may not have your typical configuration, it has the advantage of being readily available. In the face of a crisis, you will need to weigh out your options and make timely procurement decisions.

Pre-purchasing

While not all enterprises have adequate capital to save for future operational needs, investing in pre-purchase equipment is a sure way to win when others are stalling. Businesses must consider having a reserve stock to accommodate future needs. While pre-purchase technology hardware equipment may not have immediate benefits, it provides flexibility for future equipment needs.

Reusing

Re-commissioning devices and technology systems pulled out of rotation is a clever solution during this global supply chain crisis. As a stop-gap measure, look whether any decommissioned devices or systems can be reinstalled back into service. Reusing work-related technology equipment can significantly improve efficiency, mainly when a supply chain disruption is stalling other competing players.

What’s Edafio Doing During This Global Supply Chain Disruption?

Well, like many, we understand the pain of this global supply chain disruption. We strongly feel that planning and management are the most crucial things to weather out this disruption — and stay ahead. That’s why we are engineering concrete, practical solutions in managed IT services to help our clients, partners, and other stakeholders bridge gaps in their supply chains. In addition, we advise our clients to be on the lookout for new automated solutions that are replacing hardware-related tasks.